UAE Heat Treatment Center Achieves Zero-Emission Operations

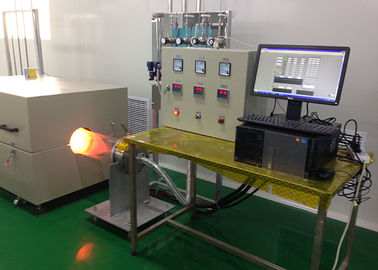

A heat treatment center in the United Arab Emirates sought to replace traditional oil-fired furnaces to comply with new environmental regulations. Their goal was to reduce emissions while maintaining high production capacity.

We introduced a large-capacity Electric Industrial Furnace optimized for continuous operation in high-temperature environments. The system included smart diagnostics, energy-saving insulation, and advanced thermal distribution technology.

Customer Feedback:

“We were surprised by the furnace’s efficiency and cleanliness. It helped us eliminate oil fumes and drastically reduce maintenance needs. Our clients also recognized the improved surface finish and consistency of treated parts. We highly recommend this equipment.”

The UAE customer later invested in an additional chamber furnace for expanding service demand, noting strong trust in the product’s reliability.

Case Study 4 – Saudi Arabia Manufacturing Group Increases Output with Advanced Electric Industrial Furnace

A leading industrial group in Saudi Arabia required a high-performance heating solution for alloy steel treatment. They needed precise temperature control to meet international standards for exported components.

We delivered a custom-built Electric Industrial Furnace featuring multi-layer insulation, a high-power heating module, and cloud-based monitoring. The smart controller allowed technicians to track temperature data in real time across multiple shifts.

Customer Feedback:

“The furnace exceeded our expectations. It runs smoothly even under 24-hour workloads and maintains very stable temperature distribution. The cloud monitoring system is extremely useful for quality audit reports. We appreciate the professional installation and after-sales support.”

The furnace received strong recognition from their engineering team, and the customer is now planning a second purchase for their upcoming facility.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!