An Introduction to Industrial Glass Furnaces

Industrial glass furnaces play a crucial role in the manufacturing of glass products used in everyday life and advanced technologies. These high-temperature facilities are designed to melt raw materials like silica sand, soda ash, and limestone into molten glass, which is then shaped into various forms such as bottles, windows, fiber optics, and more.

What Is an Industrial Glass Furnace?

An industrial glass furnace is a large, insulated structure built to withstand extreme heat, typically operating at temperatures between 1,400°C and 1,600°C (2,550°F to 2,900°F). Its main purpose is to melt and homogenize raw materials to produce a high-quality glass melt suitable for forming processes.

Types of Glass Furnaces

There are several types of industrial glass furnaces, each suited to different production scales and glass types:

-

Regenerative Furnaces: Common in large-scale operations, these furnaces use regenerators to recover heat from exhaust gases and improve fuel efficiency.

-

Recuperative Furnaces: These use a heat exchanger to preheat combustion air, suitable for medium-scale production.

-

Electric Furnaces: Powered by electricity instead of fossil fuels, they offer cleaner operation and better temperature control, often used for specialty or high-purity glass.

-

Day Tanks and Pot Furnaces: Used in smaller-scale or batch operations, ideal for art glass or laboratory use.

Key Components

-

Melting Chamber: The core area where raw materials are introduced and melted.

-

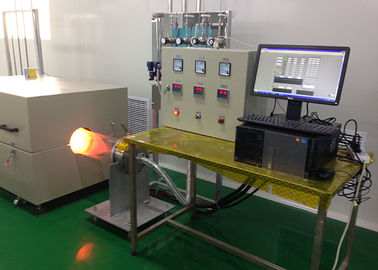

Burners or Electrodes: Depending on the fuel source (gas, oil, or electricity), these provide the energy needed for melting.

-

Refining Zone: Ensures the removal of bubbles and homogenization of the melt.

-

Forehearth: Controls the temperature of the molten glass before it is formed.

Applications of Glass Furnaces

Glass produced in industrial furnaces is used in various industries:

-

Container Glass: Bottles and jars for beverages, food, and pharmaceuticals.

-

Flat Glass: Windows, automotive glass, mirrors, and architectural panels.

-

Fiberglass: Insulation materials and reinforcement fibers.

-

Specialty Glass: Optical fibers, display glass for electronics, and laboratory equipment.

Environmental Considerations

Modern industrial furnaces are increasingly focused on energy efficiency and emission reduction. Innovations include:

-

Use of alternative fuels like hydrogen or biofuels.

-

Advanced heat recovery systems.

-

Real-time monitoring and automation for process optimization.

Conclusion

Industrial glass furnaces are the backbone of the glassmaking industry, combining advanced engineering and materials science to produce glass efficiently and sustainably. As technology continues to evolve, these furnaces are becoming smarter, cleaner, and more efficient—supporting both mass production and precision manufacturing in a wide range of applications.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!