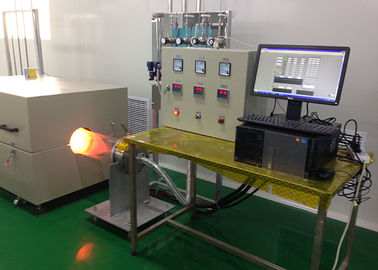

High-Temperature Electric Heating Plate Furnace Enables Stable Mass Production of Electronic Ceramics

As global demand for advanced electronic ceramics continues to grow—driven by 5G communications, power electronics, and high-performance industrial components—manufacturers are placing increasing emphasis on high-temperature stability, uniform sintering quality, and continuous production capability. In response to these requirements, the latest High-Temperature Electric Heating Plate Furnace for Firing Electronic Ceramics delivers a reliable and scalable solution for modern ceramic production lines.

Designed specifically for continuous high-temperature sintering, this electric heating plate furnace supports a wide range of structural ceramics, including 95% alumina, 99% alumina, zirconia ceramics, corundum ceramics, and advanced 5G ceramic materials. The system combines precise temperature control with modular furnace construction, ensuring long-term operational stability and consistent product quality.

One of the core advantages of this furnace lies in its excellent temperature uniformity. With a constant temperature zone uniformity of ±5°C, ceramic components experience evenly distributed thermal conditions throughout the firing process. This minimizes deformation, cracking, and density variation—critical factors for electronic ceramic substrates and structural parts.

The furnace adopts silicon molybdenum rod heating elements, known for their durability and stable performance under extreme temperatures. The maximum operating temperature reaches 1700°C, while common production temperatures range between 1400°C and 1600°C, covering most electronic ceramic sintering requirements.

To enhance automation and production efficiency, the system features a fully automatic hydraulic propulsion external circulation system, supporting both single and double push plate feeding modes. Combined with SCR power control, PID intelligent temperature regulation, and PLC + touch screen monitoring, operators gain full visibility and control over the entire firing process.

Main Technical Specifications

| Parameter |

Specification |

| Chamber Length |

9–15 m |

| Common Operating Temperature |

1400–1600 °C |

| Maximum Temperature |

1700 °C |

| Temperature Uniformity |

±5 °C (constant temperature zone) |

| Heating Zones |

5–8 zones |

| Temperature Control Points |

10–16 points |

| Heating Element |

Silicon molybdenum rod |

| Furnace Structure |

Modular assembly |

| Propulsion Mode |

Fully automatic hydraulic system |

| Push Plate Sizes |

250*250 mm, 320*320 mm (customizable) |

This high-temperature electric heating plate furnace is ideal for manufacturers seeking continuous production, reduced defect rates, and long service life. Custom configurations are available to meet different production capacities and ceramic material requirements, ensuring a future-proof solution for electronic ceramic sintering lines.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!