1. Application Scenarios

Industrial glass furnaces are used in a variety of sectors, depending on the type of glass being produced and the scale of production. Common application scenarios include:

-

Packaging Industry: Manufacturing glass bottles and jars for food, beverages, cosmetics, and pharmaceuticals.

-

Construction and Architecture: Producing flat glass for windows, curtain walls, doors, and facades.

-

Automotive Industry: Creating windshields, side and rear windows, and sunroofs.

-

Electronics and Technology: Producing ultra-thin glass for touchscreens, displays, and optical components.

-

Household Products: Manufacturing tableware, cookware, and lighting products.

-

Fiberglass and Insulation: Producing glass fibers for thermal and acoustic insulation, as well as composites used in construction and transportation.

-

Scientific and Specialty Applications: Creating high-purity glass for laboratory equipment, fiber optics, and advanced optics.

2. Manufacturing Processes

The glass production process in an industrial furnace involves several key stages:

a. Batch Preparation

Raw materials such as silica sand, soda ash, limestone, and other additives are mixed and fed into the furnace in precise proportions.

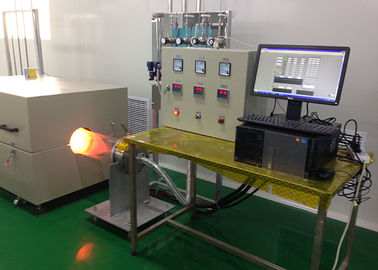

b. Melting

The batch is melted in the furnace at temperatures ranging from 1,400°C to 1,600°C. The melting zone ensures complete fusion of the materials.

c. Fining (Refining)

In this stage, gas bubbles and inclusions are removed from the molten glass to improve clarity and uniformity. This is achieved through temperature control and chemical additives.

d. Conditioning

The glass melt is gradually cooled in the forehearth to reach the ideal temperature and viscosity for forming, ensuring consistency during shaping.

e. Forming

Molten glass is shaped using different techniques depending on the product:

-

Blow and Blow / Press and Blow: For bottles and jars.

-

Float Process: For flat glass.

-

Drawing / Extrusion: For fibers or rods.

-

Pressing / Molding: For tableware and lenses.

f. Annealing

The formed glass is slowly cooled in an annealing lehr to relieve internal stresses and prevent cracking.

g. Finishing

Processes such as cutting, polishing, coating, and tempering are applied depending on the final product requirements.

3. Typical Glass Products

Industrial glass furnaces support the production of a wide range of products, including:

-

Container Glass: Bottles, jars, vials, and ampoules.

-

Flat Glass: Windows, mirrors, laminated and tempered glass.

-

Fiberglass: Insulation wool, continuous filament for reinforcement.

-

Specialty Glass: Borosilicate lab glass, display glass, optical fibers.

-

Tableware and Decorative Items: Bowls, glasses, lampshades, art glass.

Conclusion

Industrial glass furnaces are essential to the global glass industry, offering flexibility to produce a diverse array of high-quality glass products. Through advanced processes and precise control of melting and forming, these furnaces support industries ranging from packaging and construction to electronics and high-tech applications. As the demand for energy efficiency and sustainability grows, modern furnaces continue to evolve, incorporating innovative technologies to meet future manufacturing challenges.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!