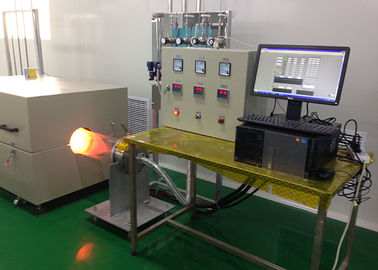

A newly developed 1300℃ Gas (Oil) Medium and Low Temperature Firing Shuttle Kiln is making waves in the fields of construction materials, refractories, and abrasives, offering manufacturers a highly efficient, flexible, and intelligent solution for medium- to high-temperature sintering processes.

Designed to meet the demanding needs of construction, refractory, and abrasive material production, the new kiln provides outstanding temperature control and operational stability. With a maximum operating temperature of 1300℃and a chamber volume range of 3–50m³, it can accommodate a wide variety of production scales — from small batch firing to large-scale industrial operations.

The kiln chamber is constructed using high-quality alumina fiber cotton and mullite insulation brick, materials known for their excellent heat resistance and insulation properties. This design not only ensures superior energy efficiency but also enhances the kiln’s durability and thermal stability during prolonged use.

Intelligent Temperature Control and Energy Efficiency

Equipped with a PID automatic temperature control system and a touchscreen interface, the kiln enables fully automated operation. Users benefit from precise temperature regulation, automatic constant temperature control, over-temperature alarms, and real-time data communication via 485 interface. With a temperature uniformity of ±5–10℃, consistent and high-quality sintering results are guaranteed.

The kiln supports multiple heating fuels, including natural gas, liquefied petroleum gas, and light oil, providing flexibility based on available energy sources. The burners are symmetrically arranged on both sides of the chamber to ensure even heat distribution, while the smoke exhaust system—available in either natural chimney exhaust or powered exhaust—ensures safe and efficient emission control.

Efficient and User-Friendly Design

To optimize workflow and safety, the kiln is equipped with a customizable electric kiln car, allowing for smooth and efficient material loading and unloading. The system can be tailored to meet specific production requirements, providing manufacturers with a practical and ergonomic solution for continuous operation.

Wide Range of Industrial Applications

The 1300℃ Gas (Oil) Firing Shuttle Kiln is ideal for the high-temperature sintering of refractory insulation bricks, building clay bricks, ceramic tiles, permeable bricks, and road stones. It is also suitable for medium-temperature firing of abrasive products such as grinding wheels, grinding discs, and polishing heads, ensuring precise material strength and structure.

Innovating Heat Treatment Technology

As part of a new generation of gas-fired automatic temperature control shuttle kilns, this product demonstrates significant advancements in energy efficiency, automation, and process control. It stands out as a reliable choice for manufacturers seeking to improve production quality while reducing energy consumption and operational costs.

For more details or customized kiln design solutions, please contact us — we are committed to creating the perfect firing system tailored to your production needs.

Tags: Grinding Continuous Mesh Belt Furnace | Grinding Wheel Mesh Belt Furnace | High Temperature Abrasive Kiln

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!