What Is an Electric Industrial Furnace and How Does It Work in Modern Manufacturing?

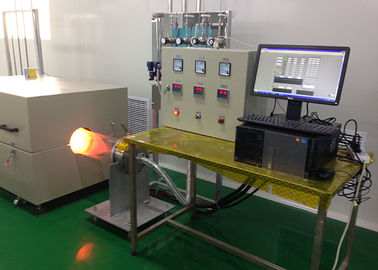

An Electric Industrial Furnace is a high-temperature heating system powered by electricity, widely used in modern manufacturing for metal processing, heat treatment, sintering, melting, and thermal testing. Compared with traditional fuel-fired furnaces, electric industrial furnaces offer higher temperature accuracy, cleaner operation, and better automation capabilities.

The working principle of an electric industrial furnace is based on electrical resistance heating or induction heating. Electrical energy is converted into thermal energy through heating elements such as resistance wires, silicon carbide rods, or molybdenum disilicide elements. The generated heat is evenly distributed inside the furnace chamber to achieve precise temperature control.

Electric industrial furnaces are commonly used in industries such as metallurgy, automotive manufacturing, aerospace, electronics, ceramics, glass, and chemical processing. Applications include annealing, tempering, hardening, brazing, sintering, and laboratory testing.

One of the key advantages of an electric industrial furnace is temperature precision. Advanced PID controllers and thermocouples allow accurate temperature regulation, often within ±1°C. This level of control is critical for industries that require consistent material properties.

Another important benefit is environmental performance. Since electric industrial furnaces do not rely on fossil fuels, they produce no direct emissions such as CO₂, NOx, or SO₂. This makes them ideal for manufacturers seeking to meet environmental regulations and sustainability goals.

Modern electric industrial furnaces can also be integrated with automated production lines. Features such as programmable logic controllers (PLC), touch-screen interfaces, data logging, and remote monitoring improve production efficiency and reduce human error.

In summary, electric industrial furnaces play a vital role in modern manufacturing by providing clean, efficient, and highly controllable heating solutions. As industries continue to move toward automation and green energy, the demand for electric industrial furnaces is expected to grow steadily worldwide.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!