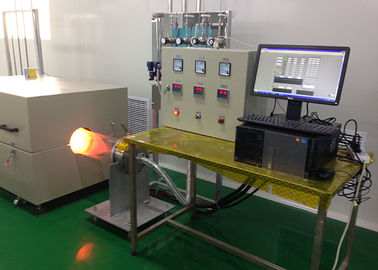

Customizable Glass Furnace Can Continuously Produce Crystal Glass Mosaic

1, Product Overview

This machine can produce different thickness of bent and melted glasses. Such as glass furniture, glass lights, glass tableware, fruits plates, mosaic etc. The height of heating section is adjustable, high precision, craft stability. Circulation continuous production. High yield, high efficiency, suitable for large glass deep-processing factories.

2, Parameter attribute table

The main technical parameters

1. Furnace length:26-60m

2. Daily output (24h) :100-1500 square meters / day

3. Heating mode:Electricity, natural gas, liquefied petroleum gas

4. Transfer method:Bevel gear transmission

5. Roller diameter:Ø40-60mm

6. Roller material:Used stainless steel rollers and high temperature ceramic rollers in

different parts of the Furnace as required

7. Roller speed:Frequency control

8. Chamber width:800-2500mm

9. Maximum use temperature:1000℃

10. Common temperature:≤900℃

11. Temperature control precision:±1℃

12. Control mode:PID intelligent control system, multipoint control

13. Furnace structure:Modular; on-site assembly.

3, Product Usage

- Non-standard customized equipment, mainly used for the continuous production of crystal glass mosaics

- Production line equipment composition: glass cutting machine, printing and drying line, breaking and typesetting machine, edge melting furnace, back film drying line and other equipment.

Our company provides a full set of technology and equipment for crystal mosaic production, please contact us for details, we will tailor it for you!

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!