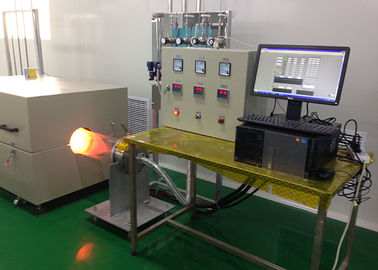

Customizable Glass Furnace Can Continuously Produce Color Glazed Glass Mosaic

1, Product Overview

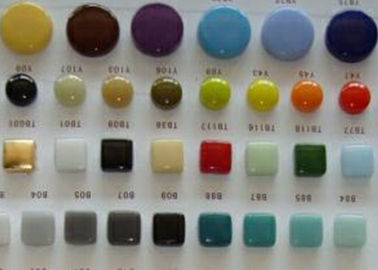

The colored glaze glass mosaic, namely parent color crystal glass mosaic is a novel glass mosaic product which is popular in recent years; a slab white glass (broken glass) is grinded, filtered, added with pigment with proper amount, stirred, and pressed by the bead machine to form plain films with various specifications; and the plain films are sintered, developed and molded.

2, Parameter attribute table

The main technical parameters

1. Furnace length:26-60m

2. Daily output (24h) :100-1500 square meters / day

3. Heating mode:Electricity, natural gas, liquefied petroleum gas

4. Transfer method:Bevel gear transmission

5. Roller diameter:Ø40-60mm

6. Roller material:Used stainless steel rollers and high temperature ceramic rollers in

different parts of the Furnace as required

7. Roller speed:Frequency control

8. Chamber width:800-2500mm

9. Maximum use temperature:1000℃

10. Common temperature:≤900℃

11. Temperature control precision:±1℃

12. Control mode:PID intelligent control system, multipoint control

13. Furnace structure:Modular; on-site assembly.

3, Product purpose

- Non-standard customized equipment, mainly used for the continuous production of crystal glass mosaics.

- Production line equipment composition: glass cutting machine, printing and drying line, breaking and typesetting machine, edge melting furnace, back film drying line and other equipment.

Our company provides a full set of technology and equipment for crystal mosaic production, please contact us for details, we will tailor it for you!

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!