Product Description:

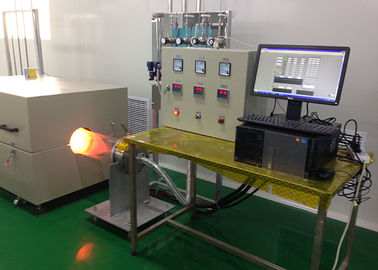

The Industrial Glass Furnace is a state-of-the-art Electric Glass Furnace designed specifically for the demanding needs of the glass manufacturing industry. With a robust melting rate ranging from 0.5 to 10 tons per hour, this Industrial Melting Furnace is engineered to deliver consistent and efficient glass melting performance, making it an essential asset for any glass production facility aiming to optimize output and maintain high-quality standards.

One of the standout features of this Industrial Glass Furnace is its box-type design, which offers excellent structural integrity and optimal heat distribution. The box furnace configuration ensures uniform melting of raw materials, reducing defects and improving the overall quality of the glass produced. This design also facilitates easier maintenance and operational accessibility, ensuring that the furnace remains reliable and efficient even under continuous industrial use.

To achieve superior thermal efficiency, the Industrial Glass Furnace utilizes high-temperature fiber blanket insulation material. This advanced insulation technology minimizes heat loss, thereby reducing energy consumption and operational costs. The high-temperature fiber blanket is not only highly durable but also capable of withstanding extreme furnace temperatures, which enhances the longevity and safety of the furnace. This insulation plays a crucial role in maintaining consistent internal temperatures, which is vital for producing glass with precise physical and chemical properties.

The application of this Industrial Glass Furnace extends broadly within the glass industry. It is ideally suited for melting various types of glass materials, making it a versatile solution for manufacturers involved in producing flat glass, container glass, specialty glass, and other glass products. Its electric heating system offers a cleaner and more environmentally friendly alternative to traditional fuel-based melting furnaces, reducing emissions and facilitating compliance with stringent environmental regulations.

Electric Glass Furnace technology incorporated in this Industrial Melting Furnace ensures precise temperature control and rapid heating capabilities. This results in improved melting efficiency and faster production cycles, which are critical factors for industrial-scale glass manufacturing. The electric heating mechanism also allows for easier integration with automated control systems, enabling real-time monitoring and adjustments to optimize furnace performance and energy usage.

Moreover, the Industrial Glass Furnace’s design emphasizes safety and ease of operation. The use of high-quality insulation materials, combined with the stable box furnace structure, minimizes the risk of heat-related hazards. Operators benefit from a safer working environment and reduced downtime due to maintenance. The furnace’s scalability, with melting rates adjustable between 0.5 and 10 tons per hour, makes it suitable for both small-scale glass production startups and large industrial glass manufacturing plants.

In summary, the Industrial Glass Furnace is a high-performance Electric Glass Furnace that combines innovative design, efficient electric heating, and superior insulation to meet the rigorous demands of the glass industry. Its box furnace type structure, coupled with high-temperature fiber blanket insulation, ensures optimal energy efficiency and consistent melting quality. Whether for producing everyday glass products or specialized glass, this Industrial Melting Furnace offers a reliable, environmentally friendly, and cost-effective solution for modern glass manufacturing operations.

Features:

-

Product Name: Industrial Glass Furnace

-

Fuel Type: Gas (Natural Gas, Oil, Electricity, Coal)

-

Material: High-grade Refractory Bricks and Steel

-

Condition: New

-

Operating Temperature: Up to 1600°C

-

Designed as a Heat Treatment Furnace for efficient glass processing

-

Equipped with a durable Furnace Heat Chamber for optimal heat distribution

-

Ideal for use in Glass Processing Machinery applications

Technical Parameters:

|

Application

|

Glass Industrial

|

|

Condition

|

New

|

|

Temperature Uniformity

|

± 3 ℃ (9 Point Test)

|

|

Fuel Type

|

Gas

|

|

Melting Rate

|

0.5-10 Tons Per Hour

|

|

Chamber Size

|

Customized

|

|

Material

|

High-grade Refractory Bricks And Steel

|

|

Service

|

Engineering Overseas Service

|

|

Fuel Type Options

|

Natural Gas / Oil / Electricity / Coal

|

|

Insulation Material

|

High-Temperature Fiber Blanket

|

Applications:

The Yanyangtian Industrial Glass Furnace is a versatile and high-performance solution designed to meet the diverse needs of the glass manufacturing industry. With its customized chamber size and ability to operate on multiple fuel types—including natural gas, oil, electricity, and coal—this furnace caters to a wide range of industrial applications. Its robust construction, featuring high-grade refractory bricks and steel, ensures durability and long-term reliability under demanding operating conditions.

This Industrial Glass Furnace is ideal for glass melting processes requiring precise temperature control and efficient fuel utilization. Its melting rate ranges from 0.5 to 10 tons per hour, making it suitable for both small-scale and large-scale production environments. The furnace is certified with CE and UL standards, guaranteeing compliance with international safety and quality requirements. With a minimum order quantity of just 1kg and negotiable pricing, it offers flexible procurement options for manufacturers.

In scenarios where energy efficiency and environmental considerations are paramount, the Electric Glass Furnace variant of the Yanyangtian product line provides an excellent alternative. This Industrial Vacuum Furnace option is particularly useful in applications demanding contamination-free environments and superior thermal control, such as specialty glass production or advanced research facilities. The electric heating mechanism ensures clean operation and precise temperature regulation, enhancing product quality.

Packaging is handled securely in containers, ensuring safe delivery within an estimated timeframe of 10 days. Payment terms are flexible, with T/T arrangements facilitating smooth transactions. The supply ability of 10 tons per year ensures consistent availability for ongoing projects or production expansions.

Typical application occasions for the Yanyangtian Industrial Glass Furnace include glass sheet manufacturing, container glass production, fiberglass melting, and specialty glass crafting. It is also well-suited for repair and maintenance workshops requiring reliable furnace solutions. Whether operating with natural gas or switching to electric power, this furnace adapts seamlessly to varied industrial scenarios, delivering efficiency and superior performance every time.

Customization:

Yanyangtian presents the Industrial Glass Furnace, a high-quality box-type furnace designed specifically for glass industrial applications. Certified with CE and UL, this furnace ensures safety and reliability in glass processing machinery operations.

Featuring a robust furnace heat chamber, the Industrial Glass Furnace supports various fuel types including natural gas, oil, electricity, and coal, providing flexibility and efficiency for diverse industrial needs. It is also compatible with industrial vacuum furnace setups to enhance processing precision.

The product is available with a minimum order quantity of 1kg, with pricing negotiable to suit your project requirements. Each unit is carefully packaged in containers to guarantee safe delivery, with an estimated delivery time of 10 days.

Payment terms are via T/T, and Yanyangtian can supply up to 10 tons per year, ensuring a steady and reliable source for your glass product manufacturing needs.

Support and Services:

Our Industrial Glass Furnace is backed by comprehensive technical support and service to ensure optimal performance and longevity. Our expert team provides installation guidance, routine maintenance schedules, troubleshooting assistance, and on-site repair services. We offer detailed user manuals and training sessions to help your staff operate the furnace safely and efficiently. Additionally, spare parts and upgrade options are readily available to keep your furnace running at peak capacity. For any technical inquiries or service needs, our dedicated support team is committed to providing prompt and effective solutions tailored to your industrial requirements.

Packing and Shipping:

Our Industrial Glass Furnace is carefully packaged to ensure maximum protection during transit. The furnace is securely wrapped with high-quality, impact-resistant materials and cushioned with foam padding to prevent any damage. The packaging is reinforced with sturdy wooden crates designed to withstand heavy handling and environmental factors.

For shipping, we employ reliable logistics partners experienced in handling heavy industrial equipment. Each shipment is accompanied by detailed documentation, including handling instructions and safety guidelines. We offer various shipping options, including sea freight, air freight, and land transport, tailored to meet the delivery timeline and budget requirements of our customers.

Upon delivery, our team coordinates with the client to ensure smooth offloading and installation support if required. We prioritize timely and safe delivery to guarantee that the Industrial Glass Furnace arrives in optimal condition, ready for immediate operation.

FAQ:

Q1: What certifications does the Yanyangtian Industrial Glass Furnace have?

A1: The Yanyangtian Industrial Glass Furnace is certified with CE and UL, ensuring it meets international safety and quality standards.

Q2: What is the minimum order quantity for the Industrial Glass Furnace?

A2: The minimum order quantity for the Yanyangtian Industrial Glass Furnace is 1 kilogram.

Q3: How is the Industrial Glass Furnace packaged for delivery?

A3: The Industrial Glass Furnace is securely packaged in containers to ensure safe transportation and delivery.

Q4: What is the typical delivery time for an order of the Industrial Glass Furnace?

A4: The standard delivery time for the Yanyangtian Industrial Glass Furnace is 10 days after order confirmation.

Q5: What payment terms are accepted for purchasing the Industrial Glass Furnace?

A5: The payment terms accepted for the Industrial Glass Furnace are T/T (Telegraphic Transfer).

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!