Product Description:

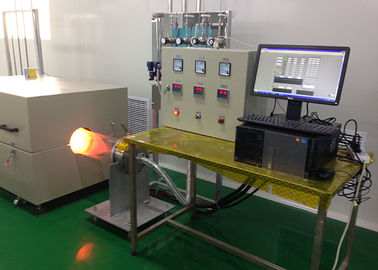

The Industrial Glass Furnace is a state-of-the-art solution designed for high-efficiency glass melting and processing in various industrial applications. Engineered to operate at temperatures of up to 1600°C, this furnace delivers exceptional performance and reliability, making it an indispensable piece of glass processing machinery for manufacturers seeking precision and durability in their production lines.

One of the standout features of the Industrial Glass Furnace is its impressive melting rate, which ranges from 0.5 to 10 tons per hour. This flexibility allows it to cater to a broad spectrum of production needs, from small-scale operations to large industrial glass manufacturing plants. The furnace’s ability to consistently melt glass at such rates ensures optimal productivity and reduces downtime, contributing to a more efficient manufacturing process.

Designed specifically for glass industrial applications, the Industrial Glass Furnace incorporates advanced technology that supports uniform heating and effective temperature control. This results in high-quality molten glass, which is critical for producing superior glass products. Whether you are producing flat glass, container glass, or specialty glass, this industrial melting furnace adapts seamlessly to your requirements, enhancing your overall glass processing capabilities.

As an electric glass furnace, this product offers several advantages over traditional fuel-based furnaces. It provides cleaner, more consistent heating with lower emissions, aligning with modern environmental standards and sustainability goals. The electric operation also allows for precise temperature management, which is crucial in maintaining the integrity and quality of the glass melt. This precision reduces material waste and improves energy efficiency, making it a cost-effective choice for glass manufacturers.

In addition to its technical excellence, the Industrial Glass Furnace comes with comprehensive engineering overseas service. This service ensures that clients receive expert support throughout the installation, commissioning, and operation phases of the furnace. Our skilled engineers provide tailored solutions and technical assistance to help you maximize the furnace’s performance and longevity, regardless of your location worldwide. This global service network underscores our commitment to customer satisfaction and operational excellence.

Investing in the Industrial Glass Furnace means opting for a robust, reliable, and technologically advanced piece of glass processing machinery that meets the demanding requirements of modern glass production. Its high operating temperature capability, versatile melting rate, and electric operation make it a standout choice for industries aiming to improve their melting processes and product quality. The addition of engineering overseas service further enhances its value, ensuring that customers receive continuous professional support and maintenance assistance.

In summary, the Industrial Glass Furnace represents the pinnacle of industrial melting furnace technology. It combines high-temperature operation up to 1600°C, flexible melting capacities from 0.5 to 10 tons per hour, and the benefits of electric heating to provide an efficient, eco-friendly, and reliable solution for glass industrial applications. Supported by expert engineering overseas service, this furnace is ideally suited to meet the evolving needs of the glass manufacturing industry and help businesses achieve superior production outcomes.

Features:

-

Product Name: Industrial Glass Furnace

-

Insulation Material: High-Temperature Fiber Blanket

-

Suitable for Glass Product processing

-

Operating Temperature: Up To 1600°C

-

Fuel Type: Gas

-

Designed as Glass Processing Machinery

-

Efficient Heat Treatment Furnace for glass materials

-

Advanced Heat Treatment Furnace technology for optimal performance

Technical Parameters:

|

Product Name

|

Industrial Glass Furnace

|

|

Product

|

Tableware

|

|

Furnace Type

|

Box

|

|

Material

|

High-grade Refractory Bricks And Steel

|

|

Chamber Size

|

Customized

|

|

Melting Rate

|

0.5-10 Tons Per Hour

|

|

Fuel Type

|

Gas

|

|

Temperature Uniformity

|

± 3 ℃ (9 Point Test)

|

|

Condition

|

New

|

|

Service

|

Engineering Overseas Service

|

Applications:

The Yanyangtian Industrial Glass Furnace is a versatile and high-performance electric glass furnace designed specifically for various industrial applications. With a robust box furnace type and an operating temperature of up to 1600°C, this furnace is ideal for processing a wide range of glass products, ensuring superior quality and precision in heat treatment operations. Its customizable chamber size allows it to cater to different production scales, making it a perfect choice for industries requiring tailored solutions.

This industrial glass furnace is certified with CE and UL, guaranteeing compliance with international safety and quality standards. Whether you are engaged in manufacturing, research, or specialized glass processing, the Yanyangtian Industrial Glass Furnace provides a reliable platform for efficient heat treatment. It is also available with a minimum order quantity of just 1kg, enabling flexible procurement options for businesses of all sizes. The price is negotiable, allowing customers to find the best value according to their specific needs.

One of the key applications of the Yanyangtian Industrial Glass Furnace is in the domain of electric glass furnaces where precise temperature control and uniform heat distribution are critical. This furnace is also suitable as an industrial vacuum furnace, capable of operating under vacuum conditions to prevent contamination and oxidation during glass treatment. Additionally, it serves as an excellent heat treatment furnace for annealing, tempering, and other thermal processes essential in glass production.

The packaging details include secure container packaging ensuring safe delivery, with a typical delivery time of 10 days. Payment terms are flexible, with TT accepted to facilitate smooth and secure transactions. With a supply ability of 10 tons per year, Yanyangtian can consistently meet high-volume demands while maintaining quality standards.

Overall, the Yanyangtian Industrial Glass Furnace is an indispensable tool in the glass manufacturing industry, supporting a variety of applications from standard electric glass furnace operations to specialized vacuum and heat treatment processes. Its adaptability, certification, and efficient delivery make it a preferred choice for industrial clients seeking advanced glass furnace solutions.

Customization:

Yanyangtian's Industrial Glass Furnace offers exceptional product customization services to meet your specific industrial needs. Our Industrial Melting Furnace is designed with high-grade refractory bricks and steel, ensuring durability and optimal performance at operating temperatures up to 1600°C.

Certified with CE and UL standards, our Industrial Vacuum Furnace guarantees safety and reliability for all glass processing machinery applications. We utilize high-temperature fiber blanket insulation material to maximize energy efficiency and maintain consistent thermal conditions.

With a minimum order quantity of just 1kg and a supply ability of 10 tons per year, we provide flexible pricing options with negotiable rates. Our packaging details include secure container shipments to ensure safe delivery.

The typical delivery time is 10 days, and we accept payment terms via T/T. This product is ideal for glass industrial applications, especially in manufacturing tableware, combining advanced technology with robust construction.

Trust Yanyangtian for customized solutions in Industrial Glass Furnace products that enhance your glass processing machinery operations efficiently and reliably.

Support and Services:

Our Industrial Glass Furnace product is backed by comprehensive technical support and services to ensure optimal performance and longevity. Our team of experts provides installation guidance, routine maintenance schedules, and troubleshooting assistance to minimize downtime and maximize efficiency. We offer on-site inspections and calibration services to maintain precise temperature control and energy consumption. Additionally, customized training programs are available for your staff to operate and maintain the furnace safely and effectively. Spare parts and upgrades are readily available to keep your furnace running at peak condition. Our commitment is to deliver reliable support throughout the entire lifecycle of your Industrial Glass Furnace.

Packing and Shipping:

Our Industrial Glass Furnace is carefully packaged to ensure safe delivery and optimal protection during transit. The product is securely wrapped with industrial-grade cushioning materials and placed inside a custom-built wooden crate designed to withstand heavy handling and environmental factors.

Each package is clearly labeled with handling instructions, including warnings for fragile components and proper orientation markers. Additionally, moisture-resistant coverings are applied to protect against any potential damage caused by humidity or water exposure.

For shipping, we collaborate with experienced freight carriers specializing in heavy industrial equipment. The furnace is transported using appropriate vehicles equipped with securing mechanisms to prevent movement and vibration during transit.

We also provide tracking information and estimated delivery times to keep our customers informed throughout the shipping process. Upon arrival, detailed unpacking and installation instructions are included to ensure safe and efficient setup of the Industrial Glass Furnace.

FAQ:

Q1: What is the brand and model of this glass furnace?

A1: The glass furnace is branded Yanyangtian and the model is Industrial Glass Furnace.

Q2: What certifications does the Industrial Glass Furnace have?

A2: The Industrial Glass Furnace is certified with CE and UL certifications.

Q3: What is the minimum order quantity for this product?

A3: The minimum order quantity for the Industrial Glass Furnace is 1 kilogram.

Q4: What are the payment terms available for purchasing this furnace?

A4: The payment terms accepted are T/T (Telegraphic Transfer).

Q5: How long does delivery take after placing an order?

A5: The delivery time for the Industrial Glass Furnace is approximately 10 days.

Q6: What packaging is used for shipping the Industrial Glass Furnace?

A6: The product is packaged in containers to ensure safe delivery.

Q7: What is the supply capacity of the Industrial Glass Furnace?

A7: The supply ability is around 10 tons per year.

Q8: Is the price fixed or negotiable?

A8: The price of the Industrial Glass Furnace is negotiable depending on the order quantity and specifications.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!