Product Description:

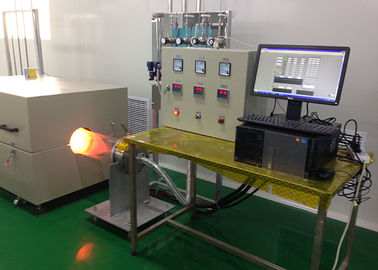

The Industrial Glass Furnace is a state-of-the-art Electric Glass Furnace designed to meet the rigorous demands of modern glass manufacturing and processing industries. Engineered with precision and built using high-grade refractory bricks and steel, this furnace offers exceptional durability, thermal efficiency, and operational reliability. It is specifically developed to provide consistent performance in various industrial applications, including glass melting, heat treatment processes, and other high-temperature operations.

One of the standout features of this Industrial Melting Furnace is its impressive melting rate, which ranges from 0.5 to 10 tons per hour. This range allows manufacturers to customize production capacities according to their specific requirements, making the furnace highly versatile for small to medium scale industrial operations. Whether you are producing specialty glass products or handling bulk glass melting, this furnace provides the flexibility and efficiency needed to optimize productivity.

The furnace chamber size is fully customizable, enabling clients to tailor the dimensions to their unique process needs. This customization ensures that the furnace can accommodate various types and sizes of materials, from small batches to large-scale production runs. The chamber's design, combined with the use of high-grade refractory bricks, guarantees excellent heat retention and uniform temperature distribution, which are critical for achieving high-quality glass products and consistent heat treatment results.

Operating at temperatures up to 1600°C, this Heat Treatment Furnace is capable of handling the most demanding thermal processes. The high operating temperature range ensures that the furnace can efficiently melt different types of glass compositions and conduct precise heat treatment cycles essential for enhancing the mechanical and optical properties of glass. This temperature capability also allows for versatility in processing other materials that require intense heat treatment under controlled conditions.

Constructed from premium steel and refractory materials, the Industrial Glass Furnace is built to withstand continuous operation in harsh industrial environments. The refractory bricks used in the furnace lining provide excellent thermal insulation and resistance to thermal shock, thereby extending the furnace’s lifespan and reducing maintenance costs. Meanwhile, the robust steel framework offers structural stability and safety, ensuring that the furnace operates smoothly and reliably over long service periods.

Designed as a new and advanced model, this Industrial Melting Furnace incorporates the latest technological advancements to enhance energy efficiency and reduce environmental impact. The electric heating system allows for precise temperature control, rapid heating cycles, and reduced energy consumption compared to traditional fuel-based furnaces. This makes it an eco-friendly choice for industries looking to improve sustainability without compromising on performance.

In summary, the Industrial Glass Furnace is an indispensable solution for any glass manufacturing or processing facility that demands high melting rates, customizable chamber sizes, and reliable operation at elevated temperatures. Its construction from high-grade refractory bricks and steel ensures durability and longevity, while its capability to operate up to 1600°C makes it suitable for a wide range of industrial applications. Whether used as an Electric Glass Furnace for melting or as a Heat Treatment Furnace for thermal processing, this product delivers superior efficiency, performance, and value, making it a top choice for industries aiming to enhance their glass production capabilities.

Features:

-

Product Name: Industrial Glass Furnace

-

Material: High-grade Refractory Bricks and Steel for enhanced durability

-

Fuel Type: Natural Gas, Oil, Electricity, or Coal options available

-

Furnace Type: Box furnace design for efficient industrial melting

-

Operating Temperature: Up to 1600°C suitable for various industrial melting processes

-

Temperature Uniformity: ± 3 ℃ (9 Point Test) ensuring consistent heating

-

Specifically designed as an Industrial Melting Furnace to meet high-performance standards

-

Reliable Industrial Melting Furnace suitable for diverse industrial applications

-

Advanced Industrial Melting Furnace technology for optimal energy use

Technical Parameters:

|

Product Name

|

Industrial Glass Furnace

|

|

Material

|

High-grade Refractory Bricks And Steel

|

|

Condition

|

New

|

|

Service

|

Engineering Overseas Service

|

|

Operating Temperature

|

Up To 1600°C

|

|

Melting Rate

|

0.5-10 Tons Per Hour

|

|

Temperature Uniformity

|

± 3 ℃ (9 Point Test)

|

|

Kind Of Glass

|

Glass Product

|

|

Application

|

Glass Industrial

|

|

Product

|

Tableware

|

Applications:

The Yanyangtian Industrial Glass Furnace is a versatile and high-performance solution designed for various industrial glass processing applications. With its robust construction using high-grade refractory bricks and steel, this furnace ensures excellent durability and thermal efficiency, making it ideal for demanding industrial environments. Certified with CE and UL standards, the Industrial Glass Furnace guarantees safety and reliability for continuous operation.

One of the primary application occasions for this furnace is in the production and processing of different kinds of glass products. Thanks to its customizable chamber size and flexible fuel options—including natural gas, oil, electricity, and coal—it can be tailored to meet the specific needs of glass manufacturers. Whether you require a melting rate of 0.5 to 10 tons per hour, the Yanyangtian Industrial Glass Furnace can be adjusted accordingly, providing highly efficient melting and heat treatment capabilities.

This furnace is particularly suitable for scenarios involving industrial vacuum furnace applications and heat treatment furnace requirements in the glass industry. It plays a crucial role in processes such as annealing, tempering, and other heat treatment procedures that enhance the quality, strength, and durability of glass products. The ability to maintain precise temperature control and uniform heating makes it an indispensable tool in glass manufacturing plants, research laboratories, and specialized production facilities.

Moreover, the furnace’s packaging in containers and flexible delivery time of 10 days, along with negotiable pricing and payment terms via TT, ensures a smooth procurement process for businesses. With a supply ability of 10 tons per year and a minimum order quantity of only 1 kg, the Yanyangtian Industrial Glass Furnace is accessible for both small-scale and large-scale operations.

In summary, the Yanyangtian Industrial Glass Furnace is perfectly suited for industrial glass melting and heat treatment scenarios requiring high efficiency, flexibility, and compliance with international safety standards. Its adaptability to various fuel types and customizable chamber sizes makes it a preferred choice for industries looking to optimize their glass processing workflows with advanced heat treatment furnace technologies.

Customization:

Yanyangtian's Industrial Glass Furnace offers exceptional product customization services tailored to meet your specific industrial glass melting needs. As a certified CE and UL manufacturer, we ensure high-quality standards and reliable performance for every unit.

Our Industrial Melting Furnace can be customized with various chamber sizes to fit your production requirements. Whether you need a Furnace Heat Chamber fueled by natural gas, oil, electricity, or coal, we provide flexible fuel type options to optimize your operation.

Designed for industrial glass applications, our furnace guarantees temperature uniformity within ± 3 ℃ (9 Point Test), ensuring consistent melting and superior glass quality. The insulation is made from high-temperature fiber blankets, enhancing energy efficiency and safety.

With a minimum order quantity of just 1kg and a supply ability of 10 tons per year, Yanyangtian offers negotiable pricing and reliable delivery times, typically within 10 days. Packaging is securely handled in containers to ensure safe transport.

We accept TT payment terms and are committed to delivering customized Industrial Vacuum Furnace solutions that match your precise specifications and production goals. Choose Yanyangtian for advanced, efficient, and customizable industrial glass furnace products.

Support and Services:

Our Industrial Glass Furnace product is backed by comprehensive technical support and services to ensure optimal performance and longevity. We offer expert installation guidance, routine maintenance schedules, and troubleshooting assistance to minimize downtime and enhance productivity.

Our team of skilled technicians is available to provide on-site support and remote diagnostics to quickly address any operational issues. We also supply genuine replacement parts and upgrade options tailored to your specific furnace model.

Training programs are available for your personnel to ensure safe and efficient operation of the furnace. Additionally, we provide detailed user manuals and technical documentation to assist with daily operations and maintenance tasks.

Our commitment is to deliver reliable, high-quality support that helps you maximize the value and efficiency of your Industrial Glass Furnace.

Packing and Shipping:

Our Industrial Glass Furnace is meticulously packaged to ensure maximum protection during transit. Each unit is securely wrapped with industrial-grade cushioning materials and enclosed within a sturdy, custom-designed wooden crate to prevent any damage from shocks or vibrations.

For shipping, we utilize reliable freight services specialized in handling heavy industrial equipment. The packaging is clearly labeled with handling instructions, and the furnace is anchored securely within the crate to avoid any movement. Additionally, we provide comprehensive documentation including packing lists, manuals, and certificates required for customs clearance.

We offer flexible shipping options including FOB, CIF, and door-to-door delivery to meet your logistical needs. Our team coordinates closely with shipping partners to ensure timely and safe delivery of your Industrial Glass Furnace to its destination.

FAQ:

Q1: What certifications does the Yanyangtian Industrial Glass Furnace have?

A1: The Yanyangtian Industrial Glass Furnace is certified with CE and UL, ensuring it meets international safety and quality standards.

Q2: What is the minimum order quantity for the Industrial Glass Furnace?

A2: The minimum order quantity for the Yanyangtian Industrial Glass Furnace is 1 kilogram.

Q3: How is the Industrial Glass Furnace packaged for delivery?

A3: The Industrial Glass Furnace is securely packaged in containers to ensure safe transport and delivery.

Q4: What is the typical delivery time for an order of the Industrial Glass Furnace?

A4: The standard delivery time for the Yanyangtian Industrial Glass Furnace is 10 days from order confirmation.

Q5: What payment terms are accepted for purchasing the Industrial Glass Furnace?

A5: Payment for the Yanyangtian Industrial Glass Furnace is typically made via TT (Telegraphic Transfer).

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!