New 1700℃ Gas (Oil) Ultra-High Temperature Firing https://www.sunnyfurnace.com/sale-12921586-1700-gas-oil-ultra-high-temperature-firing-shuttle-kiln.htmlhttps://www.sunnyfurnace.com/sale-12921586-1700-gas-oil-ultra-high-temperature-firing-shuttle-kiln.html Revolutionizes Refractory Material Production

A new generation of 1700℃ Gas (Oil) Ultra-High Temperature Firing Shuttle Kiln has officially been introduced to the market, setting a new benchmark in high-temperature sintering technology for the refractory industry.

This advanced kiln is designed for precision, efficiency, and reliability, making it ideal for the production of high-performance refractory materials, including hollow alumina products, corundum mullite ceramics, and silicon nitride–bonded silicon carbide components.

Cutting-Edge Design and Performance

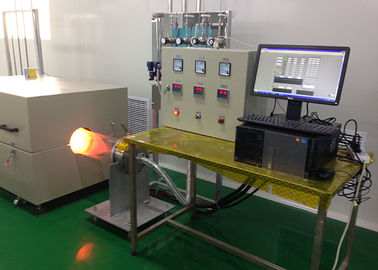

With a maximum operating temperature of 1700℃ and chamber volume ranging from 1–20 m³, the kiln provides unmatched flexibility for both research-scale and industrial-scale applications. The furnace chamber is constructed from alumina fiber board, corundum mullite, and ceramic fiber cotton, ensuring superior insulation, durability, and energy efficiency.

Equipped with a PID automatic temperature control system and touchscreen interface, the kiln offers full automation capabilities, including temperature adjustability, automatic constant temperature control, and over-temperature protection. Temperature uniformity within the chamber is maintained at an impressive ±5–10℃, ensuring consistent and precise firing results.

Energy-Efficient and Flexible Heating Options

The kiln supports multiple fuel options — natural gas, liquefied petroleum gas, and light oil — providing flexibility for different production environments. Burners are strategically arranged on both sides of the kiln for optimal heat distribution, while the waste heat utilization system combined with power exhaust greatly improves energy efficiency and reduces emissions.

User-Centered Design

For operational convenience, the kiln features an electric kiln cart design that can be customized according to the chamber volume, making loading and unloading of materials more efficient and safer.

Expanding Possibilities in High-Temperature Sintering

Engineered for industrial-grade refractory sintering, this kiln is an essential tool for manufacturers seeking high thermal stability, improved material performance, and lower energy costs.

As a representative product in the field of refractory brick tunnel kilns, gas brick tunnel kilns, and high-temperature sintering furnaces, the 1700℃ Gas (Oil) Ultra-High Temperature Firing Shuttle Kiln demonstrates innovation and reliability at the highest level of thermal technology.

For more information or customized design inquiries, please contact us — we are ready to tailor the perfect solution for your production needs.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!