Product Description:

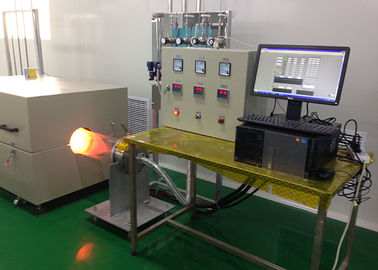

The Industrial Ceramic Furnace is a state-of-the-art heating solution designed specifically for high-temperature industrial applications. Engineered with precision and durability in mind, this furnace caters to the demanding needs of various ceramic processing industries, ensuring optimal performance and efficiency. The furnace features a spacious chamber section size ranging from 600 to 1200mm in width and 200 to 350mm in height, providing ample space for accommodating a variety of ceramic components and materials. This flexibility allows manufacturers to process multiple items simultaneously or handle larger ceramic pieces with ease, boosting productivity and streamlining operations.

One of the standout features of the Industrial Ceramic Furnace is its advanced heating element. Equipped with a U-shaped silicon molybdenum rod, the furnace delivers rapid and uniform heating across the chamber. Silicon molybdenum rods are renowned for their excellent resistance to oxidation and high-temperature stability, making them ideal for applications that require precise temperature control up to 1800℃. This ensures that ceramic materials are heated evenly, reducing the risk of thermal stress and defects, which are critical factors in producing high-quality ceramic products.

Temperature control is a vital aspect of ceramic processing, and the Industrial Ceramic Furnace excels in this area by maintaining common operating temperatures between 1000℃ and 1800℃. This broad temperature range makes the furnace suitable for various ceramics, including porcelain, technical ceramics, and advanced composite materials. Whether it is sintering, annealing, or firing, the furnace provides consistent and reliable heat treatment, enhancing the structural integrity and physical properties of the ceramics.

Durability and reliability are paramount in industrial equipment, and the Industrial Ceramic Furnace comes backed by a manufacturer warranty of 1 to 2 years. This warranty period reflects the manufacturer’s confidence in the product’s quality and long-term performance. Customers can rest assured that any manufacturing defects or issues that arise within this timeframe will be addressed promptly, minimizing downtime and ensuring continuous operation. Additionally, the furnace is built from high-quality materials and components that withstand the rigors of industrial environments, further enhancing its lifespan and reducing maintenance costs.

Understanding that each industrial application has unique requirements, the product unit price for the Industrial Ceramic Furnace is negotiable. This flexibility allows businesses to tailor the furnace specifications and pricing to match their specific needs and budget constraints. Whether a company requires custom chamber dimensions, specialized control systems, or additional accessories, the manufacturer is open to discussions to provide a solution that fits perfectly. This customer-centric approach makes the Industrial Ceramic Furnace a versatile and attractive option for businesses looking to invest in high-performance ceramic processing equipment.

In summary, the Industrial Ceramic Furnace is an essential piece of equipment for industries involved in ceramic manufacturing and processing. Its generous chamber size, robust U-shaped silicon molybdenum rod heating element, and capability to operate efficiently within a temperature range of 1000℃ to 1800℃ make it ideal for a variety of ceramic applications. Supported by a 1 to 2-year manufacturer warranty and a negotiable pricing structure, this furnace offers both reliability and flexibility. Investing in the Industrial Ceramic Furnace ensures enhanced production quality, improved operational efficiency, and long-term value, making it a smart choice for any industrial ceramic processing facility.

Applications:

The Yanyangtian Industrial Ceramic Furnace, manufactured in China, is a cutting-edge high-temperature furnace designed for a wide range of industrial applications. With a robust modular assembly structure, this Industrial Ceramic Furnace offers unparalleled flexibility and ease of maintenance, making it an ideal choice for various production environments. Its capability to reach common temperatures between 1000-1800℃ enables it to cater to processes requiring precise and consistent high heat, essential for ceramic manufacturing, metal treatment, and advanced material processing.

This Industrial Ceramic Furnace is widely utilized in industries such as ceramics, metallurgy, electronics, and aerospace, where high-temperature stability and reliability are crucial. The furnace’s modular design allows for customization according to specific industry needs, ensuring optimal performance whether stationary or mobile options are chosen. This adaptability makes it suitable for factory settings requiring fixed installations or for onsite applications that demand portable solutions.

In ceramic production, the Yanyangtian Industrial Ceramic Furnace excels in firing and sintering ceramic components, providing uniform heat distribution that enhances product quality and structural integrity. Metallurgical processes benefit from its precise temperature control, facilitating alloy treatment, annealing, and heat treatment of metals. Additionally, the furnace is employed in research and development laboratories focused on material science, where controlled high-temperature environments are essential for experimentation and innovation.

With a manufacturer warranty of 1-2 years, customers can trust the durability and performance of the Yanyangtian Industrial Ceramic Furnace. Its design prioritizes safety, efficiency, and longevity, making it a reliable asset for industrial operations requiring consistent high-temperature processing. Whether used in large-scale industrial plants or specialized production units, this Industrial Ceramic Furnace delivers exceptional results, supporting a broad spectrum of manufacturing and processing scenarios.

Overall, the Yanyangtian Industrial Ceramic Furnace stands out as a versatile and dependable solution for industries demanding high-temperature capabilities combined with structural flexibility. Its modular assembly, temperature range, and portability options position it as a leading choice for modern industrial furnace applications, ensuring enhanced productivity and product excellence across various sectors.

Customization:

Yanyangtian offers customized Industrial Ceramic Furnace solutions designed to meet the specific needs of your application. Originating from China, our Industrial Ceramic Furnace features a modular assembly structure, allowing for flexible configuration and easy maintenance. The high-temperature furnace type ensures optimal performance for various industrial processes.

We provide variable chamber sizes, typically around 300mm x 300mm x 300mm, to accommodate different material dimensions and processing requirements. Whether you require a stationary or mobile Industrial Ceramic Furnace, Yanyangtian can tailor the design to suit your workspace and operational preferences.

All our Industrial Ceramic Furnace products come with a 1-2 years manufacturer warranty, ensuring reliability and peace of mind. Trust Yanyangtian for premium, customizable Industrial Ceramic Furnace solutions that deliver efficiency and durability.

Support and Services:

Our Industrial Ceramic Furnace product is backed by comprehensive technical support and services to ensure optimal performance and longevity. Our team of experienced engineers and technicians are available to assist with installation, commissioning, and routine maintenance procedures tailored to your specific operational requirements.

We provide detailed user manuals and troubleshooting guides to help you efficiently manage and resolve common issues. Additionally, we offer training sessions for your staff to maximize the furnace’s capabilities and maintain safety standards.

For any technical inquiries or support needs, our specialists can guide you through advanced diagnostics and recommend appropriate solutions or upgrades. Preventive maintenance programs are also available to minimize downtime and extend the life of your furnace.

Our commitment is to deliver reliable service and expert advice throughout the lifecycle of your Industrial Ceramic Furnace, ensuring your investment delivers consistent and high-quality results.

Packing and Shipping:

Our Industrial Ceramic Furnace is carefully packaged to ensure safe delivery and optimal protection during transit. The furnace is first wrapped in protective foam and secured within a custom-built wooden crate designed to withstand heavy handling and environmental factors.

Each crate is clearly labeled with handling instructions and includes shock and tilt indicators to monitor the condition throughout shipping. The packaging materials are selected to prevent moisture, dust, and impact damage, preserving the integrity of the furnace components.

For shipping, we coordinate with experienced freight carriers specializing in industrial equipment. Depending on the destination, transportation options include air freight, sea freight, or land transport, with full tracking and insurance coverage provided.

Upon delivery, our team offers installation support and guidance to ensure the furnace is set up correctly and safely at your facility.

FAQ:

Q1: What industries is the Yanyangtian Industrial Ceramic Furnace suitable for?

A1: The Yanyangtian Industrial Ceramic Furnace is ideal for industries such as ceramics manufacturing, metallurgy, electronics, and materials research, where high-temperature processing is required.

Q2: What is the maximum operating temperature of the Yanyangtian Industrial Ceramic Furnace?

A2: The furnace can reach temperatures up to 1600°C, making it suitable for a wide range of high-temperature industrial applications.

Q3: Where is the Yanyangtian Industrial Ceramic Furnace manufactured?

A3: The Yanyangtian Industrial Ceramic Furnace is proudly manufactured in China, ensuring high-quality standards and advanced production techniques.

Q4: What types of heating elements are used in the Yanyangtian Industrial Ceramic Furnace?

A4: The furnace utilizes high-grade silicon carbide (SiC) or molybdenum disilicide (MoSi2) heating elements, depending on the model, to provide efficient and uniform heating.

Q5: How is temperature controlled in the Yanyangtian Industrial Ceramic Furnace?

A5: The furnace features an advanced digital PID temperature controller that allows precise temperature regulation and programmable heating cycles for optimal process control.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!