Product Description:

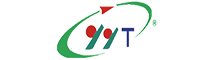

The Industrial Ceramic Furnace is a cutting-edge solution designed for high-performance ceramic processing applications. Engineered with precision and innovation, this furnace is ideal for industries that demand reliable and efficient heat treatment of ceramic materials. With an electric power rating of not less than 60KW at 380V, the Industrial Ceramic Furnace ensures consistent and powerful heating capabilities, making it suitable for a wide range of industrial ceramic manufacturing processes.

One of the standout features of the Industrial Ceramic Furnace is its modular assembly furnace structure. This design allows for easy customization and scalability, enabling users to configure the furnace according to their specific production requirements. The modular approach not only simplifies maintenance and repairs but also enhances the overall durability and lifespan of the furnace. Whether you need to expand your capacity or adapt to new manufacturing techniques, the modular assembly provides the flexibility necessary to keep pace with evolving industrial demands.

The chambersize of the Industrial Ceramic Furnace is variable, with a typical measurement of 300mm x 300mm x 300mm. This size is optimized for efficient heat distribution and uniform temperature control, which are critical factors in achieving high-quality ceramic products. The variable chamber size option means that the furnace can be tailored to accommodate different product dimensions, ensuring versatility across various ceramic applications. This adaptability makes the Industrial Ceramic Furnace an excellent choice for manufacturers who work with diverse ceramic components and require precise thermal processing conditions.

In terms of portability, the Industrial Ceramic Furnace offers both stationary and mobile options. This flexibility allows industries to select a configuration that best fits their operational environment and workflow. The stationary version is ideal for fixed production lines where stability and continuous operation are priorities. On the other hand, the mobile option caters to facilities that require the furnace to be relocated easily within the plant or between different locations, enhancing operational efficiency and reducing downtime during production changes.

When it comes to pricing, the product unit price of the Industrial Ceramic Furnace is negotiable. This approach ensures that customers can discuss their specific needs and budget constraints directly with the manufacturer, allowing for tailored solutions that maximize value without compromising on quality. The negotiable pricing model reflects the customizable nature of the furnace, where features such as chamber size, portability, and additional technical specifications can significantly influence the overall cost.

The Industrial Ceramic Furnace is engineered to meet the rigorous demands of modern ceramic manufacturing. Its robust electric power supply guarantees stable and effective heating, while the modular assembly structure offers unparalleled flexibility and ease of maintenance. The variable chamber size ensures that diverse ceramic products can be processed with precision, and the choice between stationary and mobile configurations provides operational versatility. Together, these attributes make the Industrial Ceramic Furnace a vital asset for industries seeking to enhance their ceramic production capabilities.

In summary, the Industrial Ceramic Furnace stands out as a versatile, powerful, and customizable heating solution tailored for the ceramic industry. Its high electric power rating, modular design, adaptable chamber size, and flexible portability options combine to deliver exceptional performance and efficiency. Whether you are involved in small-scale production or large industrial manufacturing, the Industrial Ceramic Furnace offers the reliability and adaptability needed to achieve superior ceramic processing results. For those interested in acquiring this advanced furnace, pricing is negotiable to ensure the best fit for your operational needs and budget.

Applications:

The Yanyangtian Industrial Ceramic Furnace, manufactured in China, is designed to meet a wide range of industrial heating needs with exceptional reliability and precision. This furnace is ideal for applications requiring high-temperature processing with excellent temperature uniformity, maintaining a constant temperature area within ± 5 ℃. Its modular assembly furnace structure allows for flexible customization and easy maintenance, making it suitable for various industrial environments.

One of the primary application occasions for the Industrial Ceramic Furnace is in the ceramics manufacturing industry, where consistent heat distribution is critical for firing ceramic products. The furnace’s silicon molybdenum rod electric heating element ensures rapid heating and energy efficiency, which is essential for processes such as sintering, glazing, and annealing ceramics. Additionally, the furnace’s design supports both stationary and mobile options, allowing factories and workshops to choose the configuration that best fits their operational requirements.

Beyond ceramics, the Industrial Ceramic Furnace is extensively used in metallurgy for heat treatment processes such as annealing, tempering, and hardening metals. Its precise temperature control and uniform heat distribution help improve the quality and durability of metal components. The modular assembly also facilitates upgrading or expanding the furnace system as production demands evolve.

In research and development laboratories, the Industrial Ceramic Furnace offers a reliable solution for experiments requiring stable and controlled high-temperature environments. Its robust construction and the manufacturer’s 1-2 years warranty provide users with confidence in its long-term performance and durability.

Furthermore, the Industrial Ceramic Furnace is suitable for industries involved in electronic component manufacturing, where precise thermal processing is vital for producing high-quality parts. The furnace’s ability to maintain a constant temperature area within ± 5 ℃ ensures minimal temperature fluctuations, which is crucial for sensitive electronic materials.

Overall, the Yanyangtian Industrial Ceramic Furnace is a versatile and dependable heating solution tailored for diverse industrial applications. Whether used in ceramic production, metal heat treatment, R&D laboratories, or electronics manufacturing, this furnace delivers outstanding performance, ease of use, and flexible installation options to meet the rigorous demands of modern industry.

Customization:

Yanyangtian offers customized Industrial Ceramic Furnace solutions tailored to meet your specific industrial needs. Originating from China, our Industrial Ceramic Furnace is crafted using high-quality ceramic insulation and refractory materials to ensure durability and optimal performance. Each furnace is equipped with a U-shaped Silicon Molybdenum Rod heating element, providing efficient and consistent heating.

We understand the importance of precise temperature control in industrial applications, which is why our Industrial Ceramic Furnace guarantees temperature uniformity within ± 5 ℃ in the constant temperature area. Our product pricing is negotiable to accommodate various project requirements and budgets.

To ensure your peace of mind, Yanyangtian provides a 1-2 years manufacturer warranty on all Industrial Ceramic Furnace units. Partner with us for reliable, high-performance Industrial Ceramic Furnace customization services designed to enhance your production processes.

Support and Services:

Our Industrial Ceramic Furnace is backed by comprehensive technical support and services to ensure optimal performance and longevity. Our team of experts is dedicated to providing prompt assistance for installation, operation, and maintenance of the furnace.

We offer detailed user manuals and technical documentation to guide you through the setup and usage processes. Our skilled technicians are available to provide troubleshooting support, helping to quickly identify and resolve any issues that may arise during operation.

Regular maintenance services are available to keep your Industrial Ceramic Furnace running efficiently. These services include inspection, calibration, and replacement of worn components to prevent downtime and extend the lifespan of your equipment.

Training programs are also offered to equip your staff with the necessary knowledge and skills to operate the furnace safely and effectively. We are committed to delivering customized solutions and ongoing support tailored to meet the specific needs of your industrial applications.

For any technical inquiries or service requests, our dedicated support team is ready to assist you, ensuring that your Industrial Ceramic Furnace operates at peak performance.

Packing and Shipping:

Our Industrial Ceramic Furnace is carefully packaged to ensure maximum protection during transit. Each unit is securely wrapped with high-quality cushioning materials to prevent damage from shocks and vibrations. The furnace is then placed inside a robust wooden crate designed to withstand heavy handling and environmental factors.

For shipping, we offer multiple options including sea freight, air freight, and land transportation to accommodate your delivery needs. The packaging is clearly labeled with handling instructions and fragile warnings to ensure safe and careful handling throughout the shipping process. Additionally, we provide tracking information and comprehensive shipping documentation to facilitate smooth customs clearance and timely delivery.

FAQ:

Q1: What is the brand name of this Industrial Ceramic Furnace?

A1: The Industrial Ceramic Furnace is manufactured by the brand Yanyangtian.

Q2: Where is the Yanyangtian Industrial Ceramic Furnace made?

A2: This furnace is made in China.

Q3: What materials can be processed using the Yanyangtian Industrial Ceramic Furnace?

A3: The furnace is designed for firing and sintering various ceramic materials, including advanced technical ceramics and traditional clay products.

Q4: What temperature range does the Yanyangtian Industrial Ceramic Furnace support?

A4: The furnace supports a high-temperature range suitable for industrial ceramic processing, typically up to 1600°C or higher depending on the model.

Q5: Is the Industrial Ceramic Furnace suitable for continuous or batch operations?

A5: Yanyangtian Industrial Ceramic Furnaces are available in models suitable for both continuous and batch processing to meet diverse industrial needs.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!